Mundra, Kutch, Gujarat

- GST NO. : 24AQLPP2518F1ZX

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Form | Powder |

| Grade Standard | Technical Grade |

| Color | Black |

| Click to view more | |

Product Details

Purity

100%

Usage/Application

Iron Ore Pellet Making

Packaging Type

Plastic Bags

Country of Origin

India

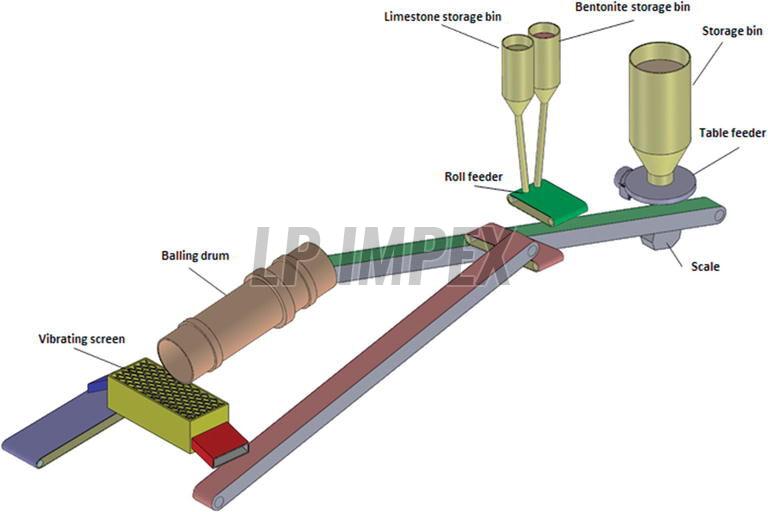

TERA BOND is an essential binding agent in iron ore pellet production. Its ability to absorb water and expand makes. it ideal for improving the quality of iron ore pellets. TERA BOND, with its higher swelling capacity, is particularly effective in this process,ensuring the production of durable and high-strength pellets.

Key Roles of TERA BOND in Iron Ore Pelletizing

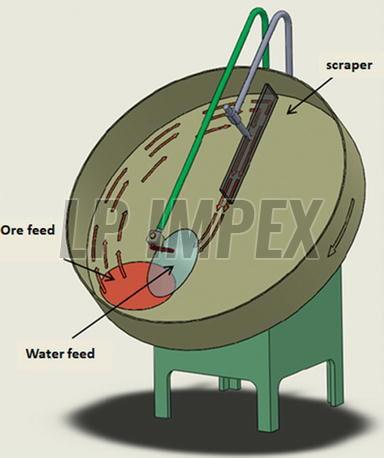

- Binder for Mechanical Strength: TERA BOND acts as a binder, aiding in the agglomeration of fine iron ore particles. This ensures that the pellets are cohesive and strong enough to withstand the handling, transportation, and high-temperature smelting process.

- Swelling and Absorption Properties: TERA BOND high water absorption capacity allows it to rapidly bind iron ore fines, forming strong, durable pellets. This property also helps in controlling moisture content in green pellets, leading to improved pellet formation and better handling.

- Thermal Stability: During the high-temperature firing process, TERA BOND maintains its structural integrity, ensuring the pellets are resistant to bursting or breaking. This thermal stability is crucial for the longevity and quality of the final product.

- TERA BOND: Preferred for its high swelling capacity and superior binding properties, TERA BOND forms stronger, more cohesive pellets, which are essential in iron ore pelletizing.

- High Plasticity: Allows for the easy formation of pellets under pressure.

- Cation Exchange Capacity (CEC): Enhances binding capabilities, ensuring tighter bonds between iron ore particles.

- Gel-like Structure: When hydrated, TERA BOND forms a gel-like structure, ensuring even distribution of moisture and binding agents throughout the pellet mixture.

- Increased Pellet Durability: TERA BOND improves the green strength (strength before firing) of the pellets, making them more resistant to handling and reducing material loss during transportation.

- Consistent Pellet Quality: TERA BOND helps achieve uniform pellet size and structure, ensuring that the pellets have consistent quality and can withstand the rigors of blast furnaces and direct reduction processes.

Chemical Analysis

| Component | Analysis |

| SiO2 | 47 % +/- 2 % |

| AL2O3 | 14 – 17 % |

| Fe2O3 | 12 – 15 % |

| CaO | 1.5 – 2.5 % |

| Na2O3 | 2.6 – 2.8 % Min |

| TiO2 | 1.5 – 2.5 % |

| K2O | 0.06 – 0.20 % |

| MgO | 2.0 – 3.0 % |

| LOI | 12 – 12.5 % |

Physical Properties

| Component | Analysis |

| Moisture | 10 - 15 % |

| Free Swelling Value | 28 - 40 ml/2g |

| Montmorillonite | 70% minimum |

| pH (5% suspension) | 9.5 – 10.5 |

| Water absorption (2h) | 420% min |

| Size | 85% Minimum passing 200 Mesh |

Looking for "Tera Bond Bentonite Powder" ?

Ton

Explore More Products